PHONE: 1-877-368-1528

PRODUCTS

FLUID INJECTION

FLUID POUR & SET

SEMI

PUTTY

APPLICATION EXAMPLES

HOME

CONTACT

BLOG

DWH potting epoxy &

casting compound for

machine construction

“Moulding in place“ is the secret behind innovative machine production and engineering.

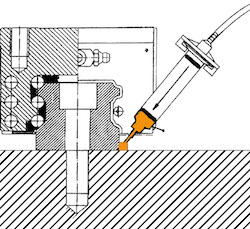

DWH adjusts the traverse beam 100% precise and forcefit to the two vertical columns. For this, the traverse was exactly aligned leaving a 2mm gap to fill with DIAMANT Fine Adjustment Coating DWH 310 FL .

Typical Applications

• all kinds of machine tools

• joints, grinding spindles, keyways

• guideways, bearing supports and flanges

• machine beds – bearings and bushings

Product Properties:

• very high precision true to measurement

• high bearing forces up to 120 N/mm2 (static)

• excellent damping and 100% forcefit-

• 100% force transfer,

• excellent adhesion

• nearly no aging or weathering

• perfect exactness to the micron

• without costly machining or

final working

Product Description

DWH is a fine adjustment coating system for connecting surfaces in machine elements and machine tools, omitting the expensive machining by the proven moulding technology.

Benefits

DWH moulds micron-exact in place making an exact copy of the surfaces they easy way.

The user can decide whether he wants a firm adhesion or a separated one that can easily be dismantled when necessary for this DIAMANT is applied before moulding.

Center, adjust, fix and optimize…

are further fields of application for DWH.

• guide pins and bushings are molded in place

• optimizing the stiffness

• screw holes are closed

• machine elements are centered

• element groups are fixed

All that without machining…

… and in 1 step with best damping properties and high cost savings guaranteed by the DIAMANT Fine Adjustment Coating System DWH for more than 5 decades, and not only in machine engineering.

DWH can be used for all metal elements which need to be longterm exact and resistant

adjusted, fixed & centered

and they improve additionally…

… the stiffness.

Guide elements are fixed inexpensively without mechanical machining highly precise, guide bushes and/or guide pins are molded in place improving the dampening, too.

More Benefits:

DWH can be used in place without special knowledge for any type of machine element.

And it is that easy:

1. roughen & clean adhesion surfaces

2. align

3. mix DWH

4. apply or inject

5. leave to cure and…

6. ready! exact to the micron.

Don't Worry Be Happy!

Example: 48" Length x 5" Width x .062" Thickness = 14.88 cubic inches x 31 (FL/P) = 461 Grams of DWH Needed

45 = DWH 310FL

31 = DWH 311 FL

32 = DWH 311 Putty

To Find the

Grams of

DWH

Required: